杆式泵锚定器

Insert pump anchor

1、 Applications

1) Insert pump anchor provides a trouble-free method of anchoring and packing off a pump in wells where a pump-seating nipple has not been provided, As a removable packoff in subsurface hydraulic-pump installations. Adjust the depth of the pump according to the rise and fall of the liquid level in the well.

2) As a casing packer in slimhole completions

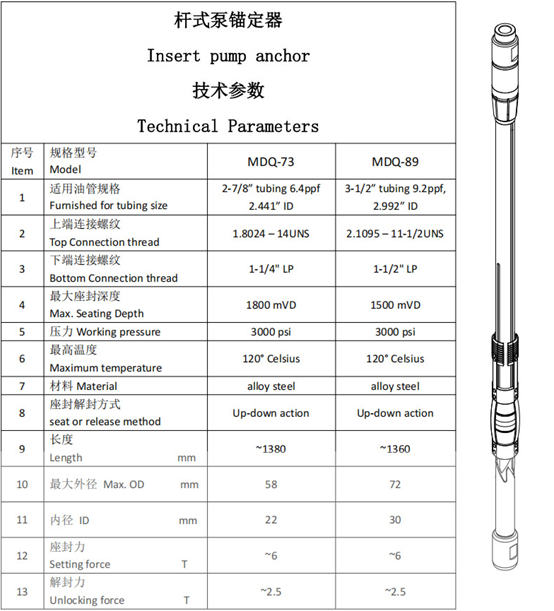

2、 Technical Parameters

3、 Bill and Materials

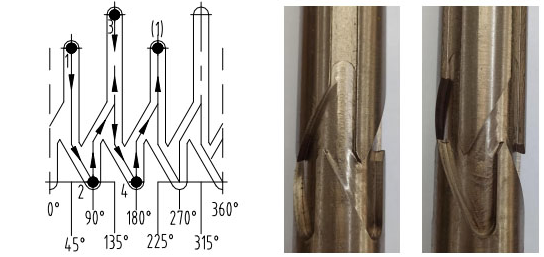

4、Working Principle

Sliding pin of sliding sleeve initial position 1 is the top of the short track of the Central tube, during the downward movement from 1 to 2, it will rotate at a certain angle due to the inclined guiding effect of the track groove , during the upward movement from 2 to 3,it will rotate at a certain angle due to the inclined guiding effect of the track groove, entering the top 3 of the long track of the Central tube, which is the seating position of the Anchor.(At this moment, the Support frame component achieves a 45 degree relative position conversion by simply moving up and down relative to the Central tube), the relative downward and upward motion from 3 to 4 and then to (1) returns to the top of the short track.

When the Support frame is at the top of short track, due to the limited of track, Anchor piece will not touch Guide Cone, the entire anchor can smoothly move down the tubing;

When the Support frame is at the top of long track, Anchor piece will touch Guide Cone, the force between the two will cause the Anchor Piece to expand and become larger, ultimately anchoring to the inner wall of the tubing, while the Guide Cone will also compress the Rubber Seal to make its outer diameter larger and contact the inner wall of the tubing to achieve sealing.

When released, lifting up the Central tube, the Guide Cone detaches from Anchor piece.

The Anchor piece loses its internal support and is released, while the Rubber seal also releases the shrink tube to unseal.

5、 Installation

The insert pump anchor is installed at the lower end of sucker rod pump to anchor sucker rod pump on the inner wall of the tubing and seals sucker rod pump and tubing.

5.1. Visually inspect the connection threads at both ends to ensure they are neat, clean, and no damage.

5.2. Connect the lower end of the insert pump anchor to the down hole tool string.

5.3 The upper joint is connected to the lower end of sucker rod pump.

5.4. When down hole operation, place the sliding sleeve and sliding pin in the end track of the central tube at the wellhead.

5.5. When insert pump anchor enters the tubing at the wellhead, due to the elastic force of the support frame, the insert pump anchor is pressed against the inner wall of tubing.

6、 Operation

6.1 Anchoring and seating.

When the pump is lowered to the set well depth, perform the anchoring and seating of the insert pump anchor.

6.1.1 Use the operating truck to lift the sucker rod, and the lifting height is greater than the stroke of the sucker rod pump and the elongation of the rod.

6.1.2 Lower the sucker rod slowly. The distance of lowering is the stroke of the sucker rod pump and the elongation of the rod. The sliding pin automatically slides from the short track to the long track. According to the working principle in Section 3, the anchoring and seating of the rod pump anchor can be achieved.

6.1.3 The complete release of the sucker rod by the operating truck indicates successful anchoring if the entire rod does not descend.

6.1.4 If the anchoring is not successful, proceed with the anchoring operation again according to 6.1.1-6.1.3.

6.2 Increase the hanging depth of sucker rod pump.

6.2.1 First, stop the pumping system and discharge all pressure inside the

wellhead.

6.2.2 Use the operation truck to slowly lift the sucker rod. After raising 3-5 pcs sucker rods, the unlocking can be confirmed.

6.2.3 After unlocking, lower the sucker rod according to the design requirements until the sucker rod pump reaches the set pump hanging position.

6.2.4 Anchoring and seating according to 6.1.

6.3 Reducing the hanging depth of sucker rod pump.

6.3.1 First, stop the pumping system and discharge all pressure inside the wellhead.

6.3.2 Use the operation truck to slowly lift the sucker rod. After raising 3-5 pcs sucker rods, the unlocking can be confirmed.

6.3.3 After unlocking, lower the sucker rod according to the design requirements until the sucker rod pump reaches the set pump hanging position.

6.3.4 Anchoring and seating according to 6.1.

6.4 Recycling.

6.4.1 First, stop the pumping system and discharge all pressure inside the wellhead.

Section 3, the anchoring and seating of the rod pump anchor can be achieved.

7、 Maintenance

7.1 Disassembly.

1) The used rod pump anchor should be cleaned of oil stains, impurities, etc. first.

2) Loosen the thread connecting the upper joint to the central tube.

3) Remove the upper joint, rubber seal, guide cone, Guide cone spacer ring and Anchor assembly from the upper end of central tube in order.

4) Loosen the thread connecting the lower joint to the central tube.

5) Remove the lower joint, support frame, sliding sleeve and sliding pin from the upper end of central tube in order.

7.2 Replacement of accessories.

1) After replacing damaged or corroded accessories.

2) Assemble the rod pump anchor in the reverse order of 7.1.

8、Features, Advantages and Benefits

1)The insert pump anchor offers complete vertical action — sets, packs off, releases, and resets without rotation — eliminating the need to pull tubing for proper depth setting of the pump.

2) Self-locking collet design sets and releases packing and slips without jamming or presetting, enhancing operational safety.

3) The anchor is automatically positioned for resetting when released and can be raised, lowered, and reset without pulling from the tubing, maximizing operational efficiency.

ADD:Room 610, Fortune Plaza, Yungang Road, Aviation Economic Zone

ADD:Room 610, Fortune Plaza, Yungang Road, Aviation Economic Zone

PHONE:+86 156 1779 7655 ; +86 187 9070 1558

PHONE:+86 156 1779 7655 ; +86 187 9070 1558

TEL:+86 371 85304855

TEL:+86 371 85304855